Thanks to this comprehensive tool, users can develop programs for industrial KUKA robots. There is support for kinematic systems manufactured by other companies.

KUKA WorkVisual

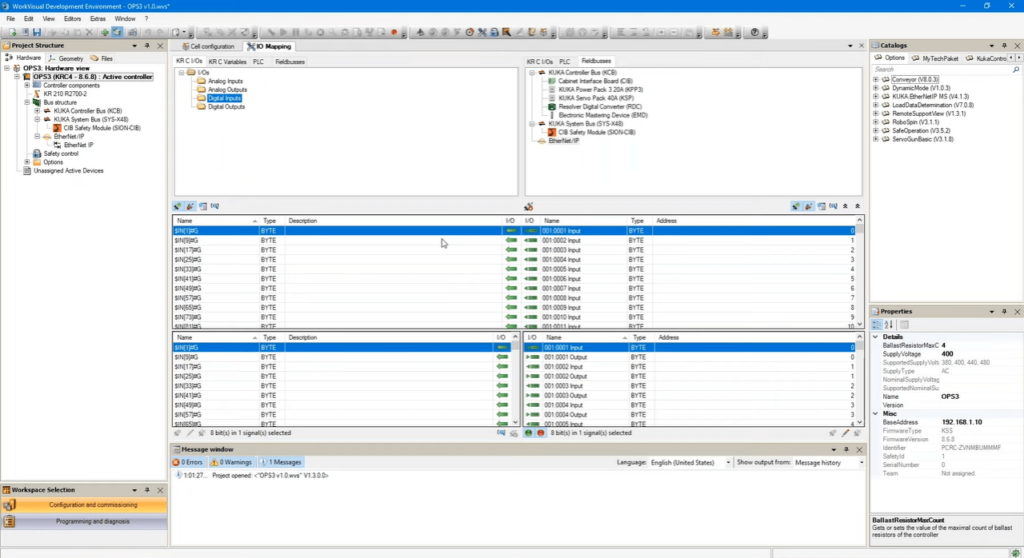

KUKA WorkVisual is a program for Windows which serves multiple engineering purposes. It acts as a versatile instrument for cell configuration, a universal programming environment, and a shop floor unit. The functionality ensures consistency between the online and offline worlds.

Automation environment

The code undergoes continuous logic checks in the background as programming steps are executed. This proactive approach guarantees that errors are identified early in the process. Visual tools are employed to make interactions more intuitive and user-friendly.

For every step, be it configuration, programming, startup, or diagnosis, the application delivers a cohesive offline development, online evaluation, and maintenance environment. Program neutral catalogs and project data are crucial, providing integration throughout the process.

Comprehensive functionality

In the modular architecture of the utility, editors and infrastructure components systematically interface with central services like the project database, catalogs, and online services. Besides fundamental features, the platform provides slots for additional modules, including Multiprog and others.

Aligned with Robot, PLC, Motion and Safety Control, the software enables direct configuration of non-KUKA kinematic systems, RoboTeams, and SafeRobot. Identifying and resolving potential conflicts can be done in offline mode. To simulate mechatronic systems, you may try a tool called SimulationX.

Features

- free to download and use;

- compatible with modern Windows versions;

- allows you to link inputs and outputs to KUKA controllers;

- you can resolve potential code conflicts in offline mode;

- there is an option to connect third party kinematic systems.